The Trio Deal!!!

Item Trio

Premium Rosewood Back + Side + Alpine Spruce Top + Ebony Fingerboards

Rosewood + Ebony Origin : India

Alpine Spruce Top Origin : Italy

We make Products from Naturally Grown trees.

The Trio Deal!!!

Description

Indian Rosewood Back + Side Set + Premium Grade

Rosewood Back and sides.

Grade AA: The logs are procured from Karnataka state of India through forest auctions which grows the best quality rosewood. They are of top quality with straight tight grains, nice color and dry material. The back and sides are made from natural forest logs.

Grade A: This material is made out of naturally seasoned logs. The material is nice quality, good color and little, good color and little wide grained as compared to grade AA material. This material is made out of fresh cut logs. The logs are brought from Uttar Karnataka state of India which grows Natural rosewood and then we select the best quality rosewood material for grade A.

Grade B: This material is made out of naturally seasoned logs. . The material will have good color, little curved grains and wide grains. This material is used by luthiers who make student guitars. The back and sides are book matched and we see to it that all our material is nicely book matched for complete satisfaction of our customers where we ship our back and sides.

Indian Ebony Fingerboards

Grade A: The material will be 100% black defect free, straight grained.

We plane our material so that the customers can see the wood quality with naked eyes.

Grade B: The material will contain stripes, curved grains. We plane our material for the

customers to see the quality of wood.

We make fingerboards for Classical guitars, Electric Guitars, Basses, Mandolins etc and also make fingerboards as per customer specifications. We do not make slotted fingerboards.

Our standard sizes are 530 x 70/60 x 9mm, 700 x 70/60 x 9mm which are always readily available from us.

The most common woods for fretboards on acoustic guitars are rosewood and ebony which is common on electric guitars too. The material of the fretboard is mostly about playability and durability.

The fretboard’s material needs to be easy for the fingers to smoothly run along and also dense enough so that it isn’t easily damaged by the strings.

That density also plays a part sound-wise. The denser the wood on the fretboard the less the tone that will be absorbed into it meaning more of the sound makes it into the soundboard.

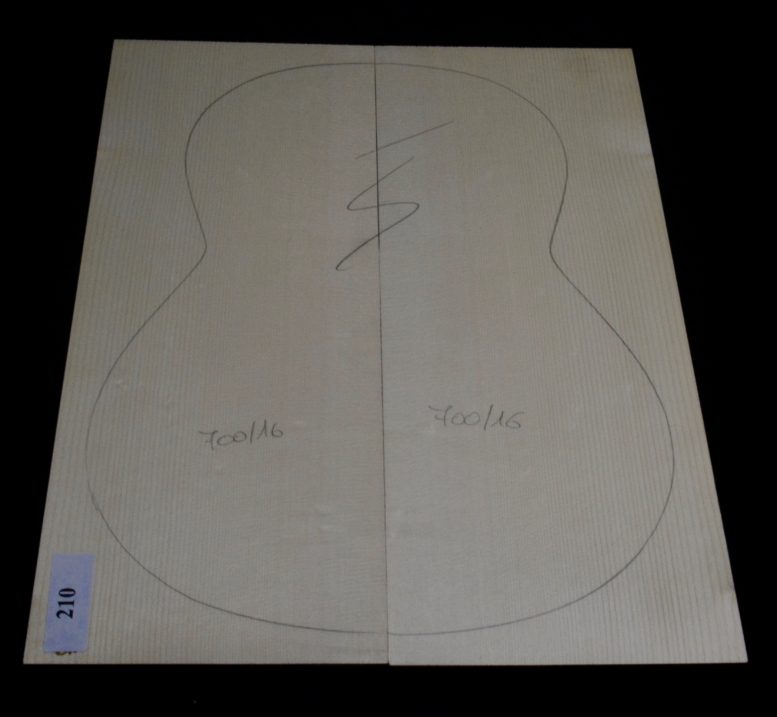

Alpine Spruce Top

The selection of SPRUCE WOOD for stringed instruments starts right in the forests of the Fiemme Valley, where the search is for logs in areas and at altitudes especially suitable to grow the best quality spruce for tone wood.

The choice is carried out among trees cut in late autumn. Extreme caution and awareness is involved in selection and cutting because of deforestation. Skilled men have been committed for several years to follow this method to the best of their abilities in order to ensure and assure that the best quality is made available for customer’s musical instruments.

The logs, after spending the winter months on the timber yards nearby the forests, are transported to a small sawmill, where they are quarter cut .

The sawn quarters are then carried to the factory, where they are sawn in perfect radial sections. After rejecting the defective parts, the wood is put on the timber yards for the natural seasoning. The pieces reserved to become tops undergo a long natural seasoning, normally between 4 and 5 years. The wood is then checked piece by piece, processed, selected and branded, according to its quality grade and seasoning year.

The planks cut at the sawmill are seasoned in the timber yards for 8 months before being carefully selected by skilled workers, and delivered to the factory.

After processing the raw planks, the seasoning is completed in a highly advanced dry kiln, where the small planks are heat treated at low temperatures for long periods of time in order not to damage the precious wood.

In the following processing steps the planks are visually inspected one by one by skilled craftsmen and cleaned from knots, flaws and all other defects. The same experience and skills are also required to “compose” the soundboards (matching the grain, colour and quality of the planks) in order to meet the customers’ precise technical and aesthetical requirements.

Shipping cost is based on weight. Just add products to your cart and use the Shipping Calculator to see the shipping price.

We want you to be 100% satisfied with your purchase. Items can be returned or exchanged within 30 days of delivery.

There are no question found.

Rating & Review

There are no reviews yet.